Copyright © WANNACRACK.COM. All Rights Reserved

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

51MB

In a word, with Schlumberger PIPESIM software, the correct amount needed to achieve the challenges of fluid flow and production optimization can be calculated.

One of the biggest concerns of engineers is the safe design of wells and pipelines so that the fluids produced reach the process facilities safely and cost-effectively. The foundation of proper modeling of production systems is based on the following three main scientific areas, all of which are included in PIPESIM:

Multiphase current modeling: PIPESIM employs a wide range of industry standard multiphase current communications as well as advanced three-phase mechanical models. This model makes it possible to calculate the flow structure, fluid latency, material motion characteristics, and pressure reduction of all stations along the production path.

Liquid Characterization Modeling: PIPESIM provides two choices for the user, one is related to industry standard black oil concepts, and the other is a range of hybrid models of equation states. Depending on the application, users can choose from a wide range of features available in the software to model a wide range of fluids.

Heat selection modeling: Accurate prediction of heat transfer is critical in calculating the temperature of the desired fluid properties in the system, the formation of solids, and, in principle, for all global thermal design. PIPESIM performs energy balance calculations calculated for a variety of heat transfer mechanisms.

Ensure safe and efficient fluid transfers: Modern manufacturing systems need designs that ensure fluids are safely and efficiently transported from tanks to process equipment. The fact that these systems exist in difficult environments, such as deep-water areas with complex infrastructure, or on large piers, adds many factors to such designs. Ability to accurately simulate a wide range of scenarios and conditions is used in the PIPESIM steady-state multiphase flow simulator, which is used as a current flow simulation tool in the design of production systems.

Production optimization: When a production system is put into operation, the ability to ensure optimal production is critical to achieving maximum economic potential. Here, too, PIPESIM software provides a complete set of workflows - from the right choice to get the job done to identifying and migrating workflow challenges and even optimizing the completed system online.

Multiphase current steady state simulator: PIPESIM software is a steady state multiphase current simulator. PIPESIM models multi-phase currents from the reservoir to the source. The efficiency of flow and surface line equipment can be calculated to produce complete production system analyzes. PIPESIM software can be integrated with the operating software production platform of Petrel E&P and Avocet to provide a single solution and a complete simulation from tanks to production.

Hardware and software requirements for this version have not been made available to the public by the manufacturer, but research has shown that the work requires moderate to high processing power.

The existing Readme.txt file contains the Crack folder.

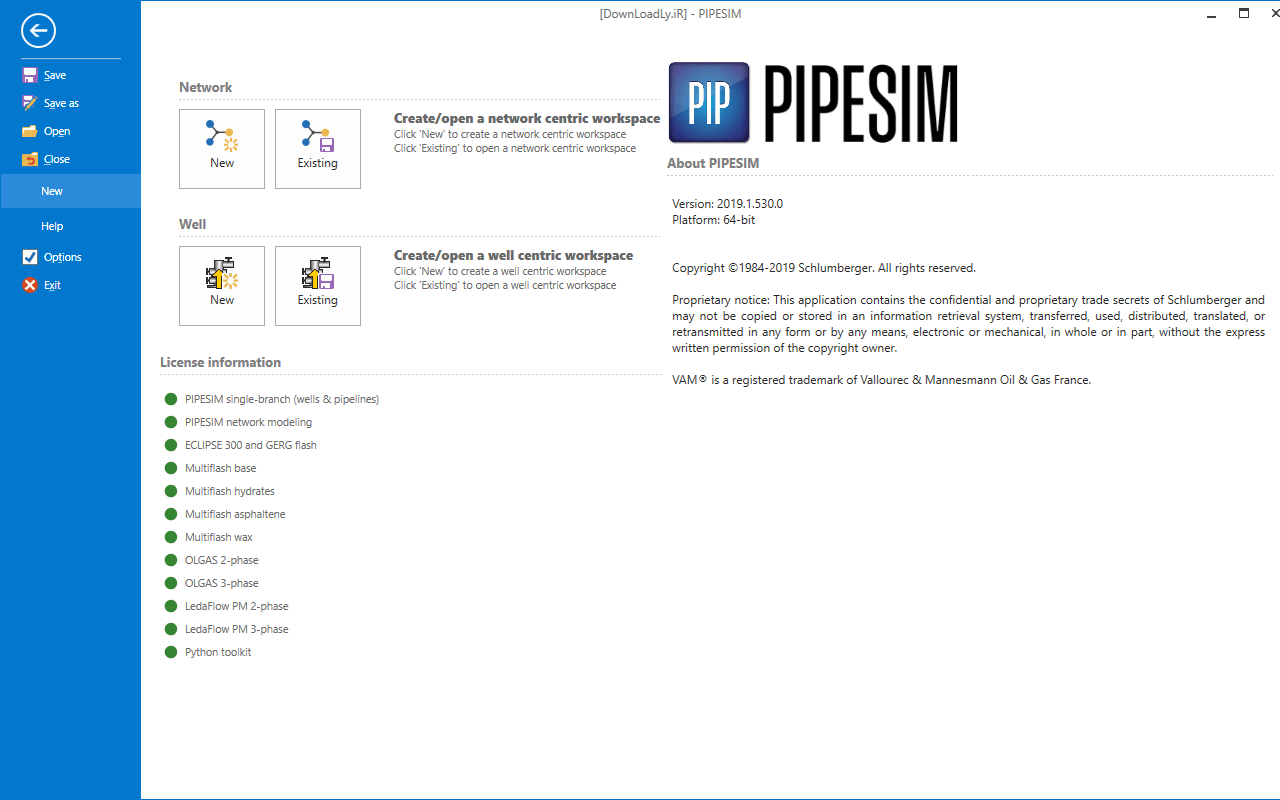

All three versions of 2014, 2015 and 2017 were installed and successfully activated on August 10, 1996 in 64-bit Windows 10.

Multiflash software is also active in both 2018.1 and 2019.1 versions.

Similar